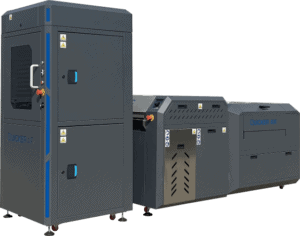

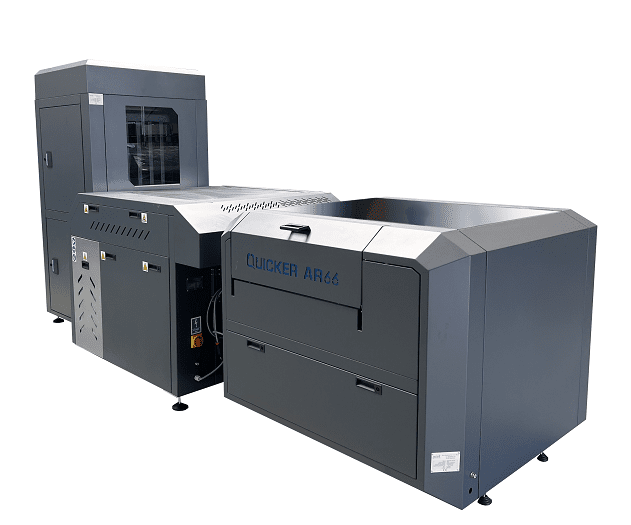

QUICKER modular Plate Washing Automation Systems

Benefits of using automatic inline polymer plate washing system QUICKER

The automatic inline photopolymer plate washing system allows simultaneous loading and cleaning of up to 25 plates of the following sizes: 660×600 mm, 960×600 mm and 1400×800 mm, depending on the size of the QUICKER C cleaner.

The QUICKER AF automatic feeder eliminates the time-consuming process of manual loading the plates into the cleaner. Even with the fastest cleaner setting in an average printing house, it can take up to several hours a day. Automation allows for more efficient use of operator’s time — reducing it by up to 90%, and the return on investment is calculated in months, not years.

How works QUICKER Inline Plate Washing Automation System?

This automatic inline photopolymer plate washing system allows for a single loading of up to 25 plates, each in a separate drawer. When the feeder is connected to the QUICKER C cleaner, both machines are automatically synchronised. Once plates are loaded, one START button on the feeder starts the whole process. The feeder QUICKER AF automatically detects in which drawer a plate is present. When the plate is located, the drawer stops at the level of the feeding table and the plate is transported into the cleaner.

The process is repeated automatically until all drawers with plates in them are empty. After the washing, rinsing and drying processes are complete, they are sent to the receiving table of the QUICKER AR. Clean plates on the receiving table are arranged in the same order as in the feeder, making it easy to archive them quickly.

The entire automatic washing process takes just 25 minutes. This includes loading 25 plates into the feeder, which is done by the operator and takes two to three minutes.

The result is a perfectly washed, dry and ready re-use plate.

The operator’s role is limited to loading and starting the process with the START button.

Recommended cleaning liquids for flexo plates

QUICKER Cleaner SOLVENT

QUICKER Cleaner UV QLine

QUICKER Cleaner UV

QUICKER Spray-On Cleaner

QUICKER Spray-On Cleaner