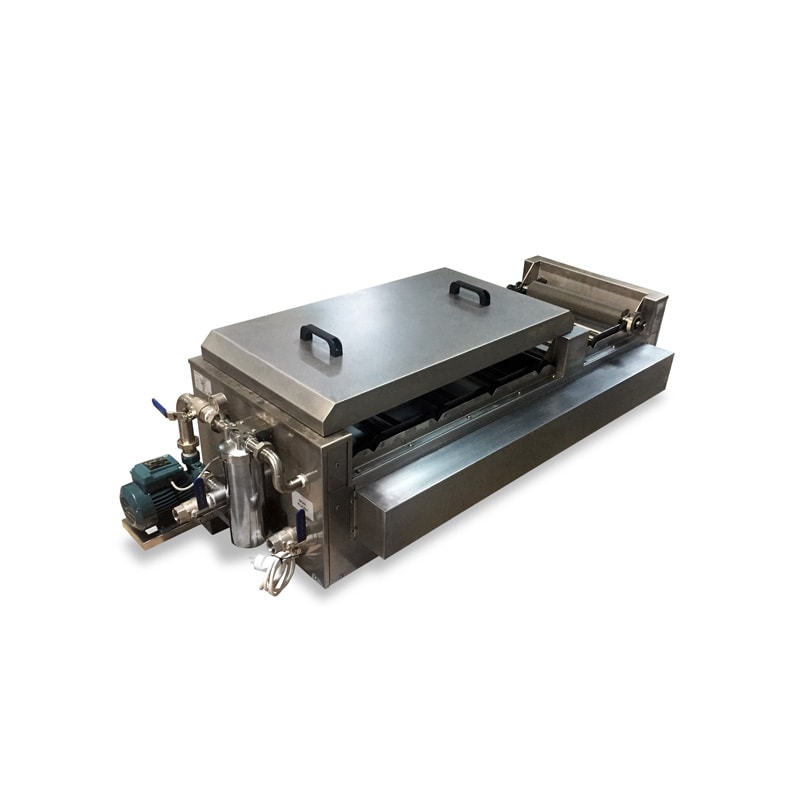

Ultrasonic anilox cleaning machine QUICKER U

The ultrasonic anilox roll cleaner QUICKER U is individually designed to meet the needs of your printing house. The QUICKER anilox and sleeve cleaner work effectively with all types of inks with the use of dedicated anilox roller cleaning chemicals.

The ultrasonic anilox roll cleaner QUICKER U is individually designed to meet the needs of your printing house. The QUICKER anilox and sleeve cleaner work effectively with all types of inks with the use of dedicated anilox roller cleaning chemicals.

Fully automated process for smarter and safer maintenance of the rolls. The perfect cleaning effect helps to reduce set-up times, minimize press downtime, increase the lifetime of the rolls and optimize printing quality. All about anilox cleaning solutions>

Ultrasonic anilox roll cleaner is manufactured by Print Systems.

Advantages of the QUICKER ultrasonic cleaner:

A combination of ultrasound waves and a cleaning agent is used to thoroughly wash the roller. The anilox rotates in the heated chemical agent solution (e.g. caustic soda). Ultrasound waves activate a cavitation process, forming gas bubbles whose implosion on contact with the anilox surface releases pressure and temperature that help dissolve and destroy contamination in anilox cells. The ultrasonic cleaner is a smart investment, as it provide the most delicate cleaning of your aniloxes.

Short and gentle cleaning process leaves the rolls perfectly clean and ready for use in 25 minutes without causing any wear or tear to the roll.

The ultrasonic anilox cleaner can be fitted with single or double frequency. The lower frequency in ultrasonic cleaning is better for bigger anilox cells. The lower frequency tends to clean more aggressively, so larger cells can handle the action. For more sensitive, smaller anilox cells and delicate cleaning is best to use higher frequency. In the higher frequencies, the waves are able to penetrate through small cells and crevices more easily.

Installation and set up is quick and easy.

The water consumption is very low and the ultrasonic anilox rolls cleaner QUICKER U have a built-in cleaning agent circulation system which allows re-use of the liquid.

A combination of ultrasound waves and a cleaning agent is used to wash the roll. The anilox roll rotates in the heated chemical agent solution (e.g. caustic soda). Ultrasound waves activate a cavitation process, forming gas bubbles whose implosion on contact with the anilox roll surface releases pressure and temperature that help dissolve and destroy contamination in anilox cells. Read all about anilox cleaning solutions>

Explore more QUICKER cleaning solutions – plate washer, parts cleaning machine.

QUICKER U500

Example of machine configuration

Maximum anilox length

Machine dimensions

Power supply

Additional connections required

Liquid tank capacity

Water tank capacity

500 mm

W. 850mm H. 1100mm L. 680mm

230[V] 50[Hz]

Air connection 6 bars

2o[l]

2o[l]

Ultrasonic anilox roll cleaning machine - how it works?

Recommended cleaning liquids for anilox rolls

QUICKER Anilox Ultra

QUICKER Anilox Neutral

QUICKER Anilox Gel

QUICKER Anilox APC